Is Viscose Rayon a natural textile fibre?

Is Viscose Rayon a natural textile fibre?

…What are wood fibre, eucalyptus fibre, beech fibre, bamboo fibre really?

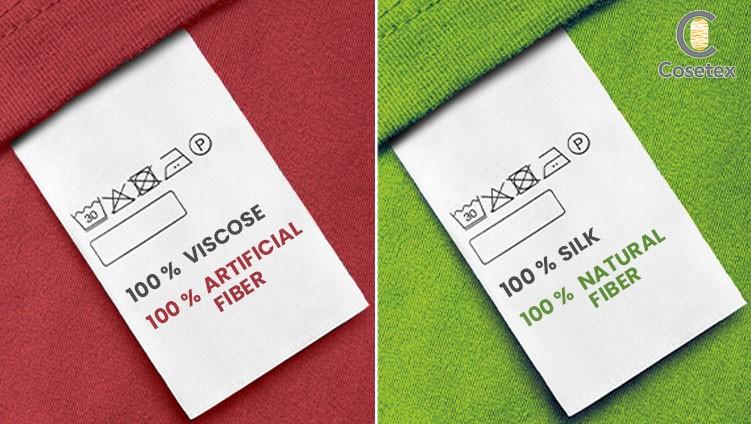

Viscose or Rayon is an artificial fiber.

Silk is a natural fibre, a natural microfibre, sustainable and eco-friendly.

It is becoming more and more common to come across, buy, and/or see products advertised that are composed of viscose fibres, (born as artificial silk), labelled or promoted as natural wood fibres, eucalyptus fibres, cellulosic fibres, bamboo fibres, Lyocell, modal, micro modal, residues from orange peel, wine residues, milk, etc.

It is necessary to really understand if you are approaching a real natural fibre, as often stated by misleading ads and marketing policies, or something else.

Research data and laboratory tests on viscose

A series of laboratories, including the authoritative Good Housekeeping Institute, have carried out in-depth analyses on products marketed as containing natural fibres derived from bamboo, wood, eucalyptus or beech, (Lyocell/Tencel), carrying out tests of their actual composition. The results are incontrovertible:

The results are incontrovertible:

“Rayon is the generic term for fibres produced from vegetable cellulose. Types of rayon include viscose, lyocell, and modal. Although they are similar, they vary according to the production steps. The process of making the fabric from bamboo, eucalyptus or another tree begins with the plant, however, the plant raw materials are chemically dissolved to the point that they no longer exist in the final fabric. All that remains is the cellulose, which is then processed with more chemicals and transformed into fibres”.

– Lexie Sachs, textile director of the GH Institute

“In relation to the plants used as material, the pulp obtained mainly contains chemically treated cellulose. Everything that refers to the original plant is removed”.

– Anil N. Netravali, Ph.D. Professor of fiber science and apparel design at Cornell University

“For most of the 20th century, viscose rayon production was inextricably linked to widespread, serious and often lethal diseases among those who produced it. Regular exposure to high levels of carbon sulphide has been shown to damage the nervous system”.

“If you buy something that also contains 50 percent viscose rayon, don’t fool yourself that you are buying a “green” product”.

“The factories are so polluting and dangerous to health that it is no coincidence that the US production of viscose has closed or delocalised”.

– Paul D. Blanc, professor of occupational and environmental medicine at the University of California, San Francisco, and author of the book “Fake Silk: The Lethal History of Viscose Rayon”

The real composition of synthetic fibres

We are unequivocally faced with a series of synthetic fibres, defined as rayon or viscose, invented in 1883 by the French chemist Hilaire Bernigaud (see photo) with the aim of reproducing some characteristics of Silk (lustre and soft feel) through chemical processes to sometimes very invasive (with the use of sodium hydroxide and carbon disulfide), starting from vegetable cellulose or other proteins of animal/vegetable origin, the elements of which are completely destroyed during the production process.

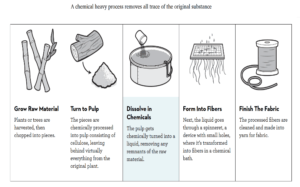

How does a plant become Rayon or viscose

The process by which a plant, a natural element, becomes Rayon (therefore artificial), is the following:

The process by which a plant, a natural element, becomes Rayon (therefore artificial), is the following:

Raw material – The plants or trees are collected and chopped up

Semi-finished product – The individual pieces are shredded and transformed into pulp through a chemical process. The elements of the original plant tend to disappear.

From pulp to liquid – Through a chemical process, the pulp is transformed into a more or less dense liquid. There are no longer any elements of the original plant

Fibre – By means of an extruder, the liquid is transformed into a filament (thread).

Finishing – The filaments (threads) are processed to make them suitable for weaving.

What the Rayon/Viscose labeling law says

The US legislation, always very attentive to health, labelling, and Greenwashing issues affirms, through the authoritative Federal Trade Commission (FTC), the right to refer to the natural raw material with the mandatory use of the name rayon or viscose (Bamboo viscose and not bamboo fibre).

On the contrary, companies are increasingly omitting this description, both on products and in marketing campaigns, with the aim of making the final consumer perceive that that particular fibre contains only natural elements. (Bamboo fibre is different from bamboo viscose, wood fibre is different from wood cellulose viscose)

To understand how this issue is perceived as serious and harmful, the FTC provides a brief guide on its website “How to Avoid Bamboozling Your Customers” in order to create precise rules to combat illegal practices and/or greenwashing.

In addition to the environmental impact related to the use and release of chemical substances, the overall eco-sustainable aspect must also be carefully evaluated according to the large quantities of trees that are felled to obtain the cellulose that is used for the viscose manufacturing process.

Lexie Sachs Bachelor of Science degree in Fibre Science from Cornell University, researcher and analyst specialising in linens, bedding, furnishing fabrics and clothing. Consultant as a textile expert for major media outlets such as The New YorkTimes, The Washington Post, Good Morning America and NBC News. She has been part of the Good Housekeeping team since 2013.

The Good Housekeeping Institute, established in 1909 and based on the 29th floor of the Hearst Tower in Midtown Manhattan, tests thousands of products every year in its six locations. Good Housekeeping Magazine is one of the most authoritative publications in the United States. For more than a century, it has analysed products to verify their safety and benefits for the final consumer.